New Federal-Mogul Powertrain piston skirt coatings increase durability and reduce engine friction

Federal-Mogul Powertrain has introduced two innovative piston skirt coatings (one for gasoline engines, and one for diesel), composed of a metal oxide-reinforced resin with additional embedded solid lubricant particles. The new formulations deliver reductions in internal engine friction, wear and noise, while enduring the loading and temperature characteristics typical of new, smaller, turbocharged engines. As explained by Dr. Frank T.H. Dörnenburg, Head of Technology, Global Pistons at Federal-Mogul Powertrain:

The piston skirt and piston pin alone account for around 17 percent of the frictional losses in an engine. Skirt coatings have proved to be an effective way of meeting the interrelated targets of reduced friction and wear between piston skirt and cylinder surfaces, used in combination with optimum piston clearance and skirt geometry. Application of the piston skirt coatings using a fully automated, large-scale production process means that the excellent wear and friction properties can be achieved within economical cost targets.

The coating, which is applied in a thickness of 15 microns, reduces skirt wear in gasoline engines by up to 40 per cent compared to the market standard and reduces friction by up to 15 per cent compared to standard coatings, directly improving the efficiency of the base engine.

The Tech-K.O. Takeaway: The more that engine friction can be reduced, the closer we get to the theoretical limits of engine efficiency. New friction- and wear-reducing coatings will have to keep pace with the changes in base engine alloys, as the move to lighter, stiffer metals progresses.

- Full story at Green Car Congress.

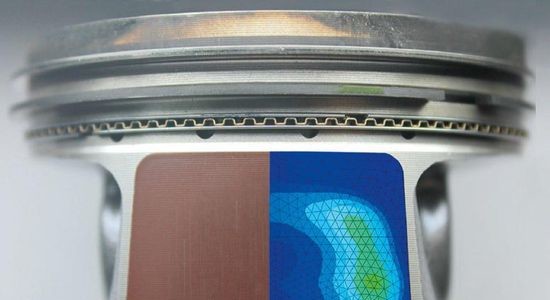

- Photo: Federal-Mogul Powertrain’s new piston skirt with coating (Green Car Congress).